Here’s a little of the stuff that has been keeping me occupied since we started our new urban farming business at the beginning of 2012.

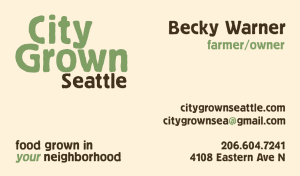

On the business development side, I have now signed an L.L.C. Operating Agreement, used my U.B.I. to open a bank account, bought fertilizer using an Agrigultural Reseller Permit, ordered business cards, and learned that I have absolutely no idea how to do accounting.

On the physical labor and general ruggedness side: I have been using the heck out of that drill my Grandfather gave me (hey Grampa)! I now know to ask for self-tapping screws at the hardware store. I am getting comfortable using a miter saw. Oh, and I drive a truck now. That’s a new thing. I used my new truck to drive 500 lbs of ground limestone, 250 lbs of organic chicken manure fertilizer, and 10 cubic feet of potting soil home from the agricultural supply store in Snohomish.

On the actual farming side, I don’t really have that much to brag about yet. Haven’t grown anything yet. But I have been digging around in the dirt a lot, and at this point I can at least fake it that I know what I’m talking about when examining soil as to whether it has a high proportion of sand or clay as opposed to being a silty loam!

Overall, I’ve been learning how to be my own boss. It’s about finding the right balance between talk and action. My business partners Noe and Scott and I have been having plenty of three-hour planning meetings where we talk about all the myriad of things that need to happen for our business to move forward into a moneymaking phase. There are lots of pieces that need to come together, and they all need to be talked through, but if you spend too much time talking about them, you won’t have enough time to actually get them done. At some point you need to follow up on your planning, turn your talk into action, and then be ready to adjust if/when realities don’t match up with your hypotheticals.

For one example, take a single crop of the 25 or so that we’ve decided we want to grow this year. Onions – if we want to harvest them in September, we need to start them from seed in February. Oh wait, it is February. Good thing we bought those seeds back in January. But we need to have a place to plant those seeds where they will germinate and thrive even in the February cold. We need a greenhouse. Then it’s about tracing that need back through all the steps that need to happen to get us there and mapping out a plan. First decide on dimensions and design. Then source and buy materials and recruit extra hands to help build. Then go outside and actually build, navigating little hurdles like not enough screws and drills running out of batteries. Take an extra few days to finish up the greenhouse end walls and create a table for the plant starts to sit on. And then finally, plant the seeds. And then follow up! You’re not done as soon as the seeds are in the ground. It’s only after planting that you might realize that the greenhouse is not actually warm enough to germinate seeds right now, so now you’re buying heat mats and insulation to add some extra degrees F. The reward is now, 7 days after planting, the seeds are up and growing. Yay! Quick pause to smile and celebrate with Noe as we check on them and see the green needles poking up out of the soil in the trays. Then it’s on to the next step, keeping those little sprouts healthy. And starting the next round of crops – tomatoes in a week, brassicas and lettuce a few weeks after that. And simultaneously prepping the ground that they will eventually be transplanted into so that it’s ready and waiting at the proper time. We have time to add compost to the plots right now, but Noe and Scott tell me that it’s too early from a fertility perspective — the winter rains will just wash the nutrients down and out into the Puget Sound, nullifying our work and expense and potentially polluting at the same time. So I, the eager beaver, have to wait until Noe gives me the go-ahead that the ground is warm enough that those little soil microbes will wake up out of their winter slumber and be ready to chew up our added compost and lock its nutrients into the ground for our plants’ exclusive usage. Or at least that’s what I envision them doing. This is what’s great about having a team of three. Each of us contributes a different skill set and background, so although none of us is an experienced farmer, by sharing the little bits of proper management that we each know, as a whole we hopefully have enough smarts to get enough of this farming thing right.

For me it’s super great to be able to draw on both of my prior two years of apprenticeship experience as I feel my way through each farming decision as it comes up. I am constantly thinking back and remembering, How did Brian do this particular thing? How did Betsey? How did the dudes at Oxbow? Sometimes I go with one mentor’s system and sometimes another; sometimes neither works for our particular situation, and sometimes I’m lucky enough to realize that both past farms did the same thing so I can be pretty sure that way is right 🙂 I am also lucky to have those former mentors to ask questions that come up. For example I mentioned driving my truck to the agricultural supply store. A month ago we were wondering, where do farmers go shopping? A quick email to Betsey revealed that all farmers in the Puget Sound region shop at this one store in Snohomish. They don’t have a website, only a catalog from 2009, and you have to know what to ask for when you walk in the door or else they will look down upon you as a pesky home gardener. But they will have your greenhouse plastic in stock and very cheap prices on the best quality potting soil. So now we know.

But I can’t ask Betsey about every little thing. Making decisions all by myself about things like crop varieties to grow, planting dates, application rates for amendments, etc, is scary the first time through. But it’s what I wanted. It’s that step out of the safety net of following a boss’ instructions into the unknown of living with the consequences of your own choices. I am not good at making quick decisions — my Libra nature can always see both sides! — and I usually spend far too long over-analyzing and deliberating on even the smallest choice between two options. But the need to move things along with this business is helping me work on that. I feel good each time I am able to make myself just say “okay, let’s go for it,” even if I am just saying that out loud to Noe and Scott while inside my head is saying “oh but wait, what if we did this other thing instead, would that be better in any way?” I think working with Scott is helping me with this. He has a “just get it done” attitude that is a good balance with my and Noe’s general attitude of detail-oriented pre-planning.

As if it were not enough to take on starting a new business, I am also newly elected to my first ever board of directors this year. I grew up with my Dad always being on one Board or another, and I’m glad to be following his example of volunteering some time out of my life to go “do the people’s business” as he would say. But it feels like a lot — with a more than half time “real job,” a more than half time farming job, a couple of volunteer organizations to keep up with, and trying to be a contributing roommate/animal husbander at this awesome house I live in, my social life is sure to suffer 😉

But it’s going to be an exciting year for City Grown and for me personally. So far it has been continually challenging and fun. I hope to keep finding time to blog about it although I may soon move some of my writing over to a potential blog on the City Grown site itself. Thanks, blog readers, for reading and commenting. The point of the City Grown venture is to grow food for our community, so if you’re reading this I hope to see you at the farm!

Filed under: construction, Seeds, the day to day | 8 Comments »